ENGINEERING SERVICES & PRODUCTS

SAND FILTER SYSTEMS

Why Removing Suspended Solids Is So Important for your boilers

Water used in palm oil mills usually comes from rivers or ponds, which contain a lot of fine dirt, clay, and organic matter — also known as suspended solids. If this dirty water goes directly into the boiler, those particles will settle inside the tubes and form hard scale or sludge. Even a thin 1 mm layer of scale can reduce the boiler’s heat transfer efficiency by up to 10%, meaning you burn more fuel just to produce the same amount of steam.

By installing a sand filter, most of these suspended solids can be removed before the water enters your softener or RO system. Typically, a well-designed sand filter can reduce suspended solids by up to 90–95%, lowering turbidity from around 100–300 mg/L to below 10 mg/L. Cleaner water means less scaling, fewer chemical treatments, and more stable boiler operation.

Over time, this improvement translates to 3–8% better boiler efficiency, less blowdown, and longer equipment life — saving thousands in maintenance and fuel costs every year. For palm oil mills running large biomass boilers, that difference adds up quickly.

Built for Industrial Reliability

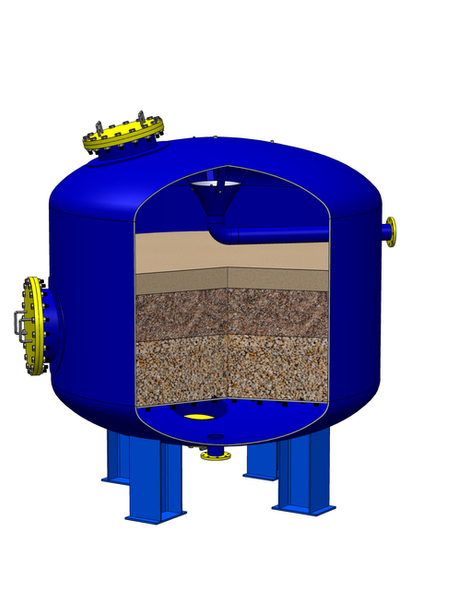

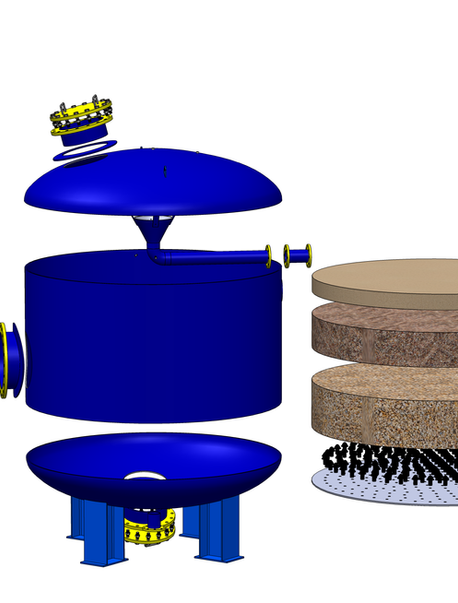

Our sand filters are designed and fabricated to handle the high water demands of large palm oil mills and biomass boilers. We regularly build units ranging from 1.6 m to 2.7 m in diameter, with shell lengths up to 2 m. These heavy-duty pressure vessels can deliver flow rates between 20 m³/hr and 100 m³/hr per unit, depending on configuration and media depth.

Each filter is constructed for continuous industrial operation, using mild-steel or stainless-steel tanks with epoxy coating and robust internal distributors. Whether your mill runs a 30 TPH or 80 TPH boiler, our systems provide reliable, consistent water quality for boiler feed, cooling, or process reuse applications.

Problem & Solution:

Sand Filtration for Palm Oil Mills

Raw and untreated water in palm oil mills often contains high suspended solids such as sand, silt, and turbidity, which can foul boilers, water softeners, and RO systems, leading to frequent maintenance, downtime, and reduced efficiency. Our pressure sand filter solution addresses these issues by using multi-grade sand media to effectively remove suspended solids through a controlled filtration process, producing cleaner water that protects downstream equipment, improves system reliability, and ensures stable mill operations.

Over 50+ units installed in Malaysia

Flexible Material Options

We can construct filters from mild steel, stainless steel, or FRP-laminated steel for added corrosion protection. This flexibility ensures long service life even under harsh, high-humidity palm oil mill environments.

Optimized Sand Bed Design

Our engineers can tailor the sand media grading and depth to achieve the right balance between filtration efficiency and backwash frequency — keeping your water clean without excessive downtime or water loss.

Automation Ready (PLC Integration)

We can equip your system with PLC-controlled backwash functions, allowing automatic cleaning cycles and minimizing operator error. This ensures consistent performance and reliable operation, even during shift changes.

Finishing Options for Durability

Choose from sandblasted surfaces, epoxy coatings, or industrial paint finishes, depending on your site condition and maintenance preference. Every unit is prepared for long-term operation under continuous mill use.

Compact Units to Large-Capacity Systems

We design and fabricate sand filters ranging from small compact units (700 mm diameter) all the way up to large industrial vessels exceeding 3,000 mm in diameter. Whether you need a filter for a small process line or a full-scale palm oil mill boiler feed system, we have the in-house expertise to deliver the right solution.

Our engineering team uses CAD-based design and 3D modeling to ensure each unit fits perfectly into your site layout and piping arrangement. This allows us to optimize space, flow direction, and maintenance access, ensuring smooth integration with your existing water treatment setup.

With a range of ready stock sizes — such as Ø2300 × 1200 mm, Ø2743 × 1219 mm, Ø2440 × 1680 mm, and Ø3000 × 1700 mm — and the ability to custom-build beyond these dimensions, we can tailor every sand filter to meet your specific capacity, pressure, and installation requirements.

Working With the Best Clients and Partners

Contact us today

Malaysia, 8, Jalan Mahsuri, 4 1/2 Miles, Jalan Mersing, Kawasan Perindustrian Kluang, 86000 Kluang, Johor